Buildings and industries annually lose millions of dollars due to hidden energy leaks, such as steam, HVAC, power, and gas, which result in increased CO2 emissions.

Your AI-PoweredCopilot for EnergyEfficiency—featuringthe first-ever CO2Validation stamp-redefining how theworld sharessustainabilityefficiency, and CO2achievements.

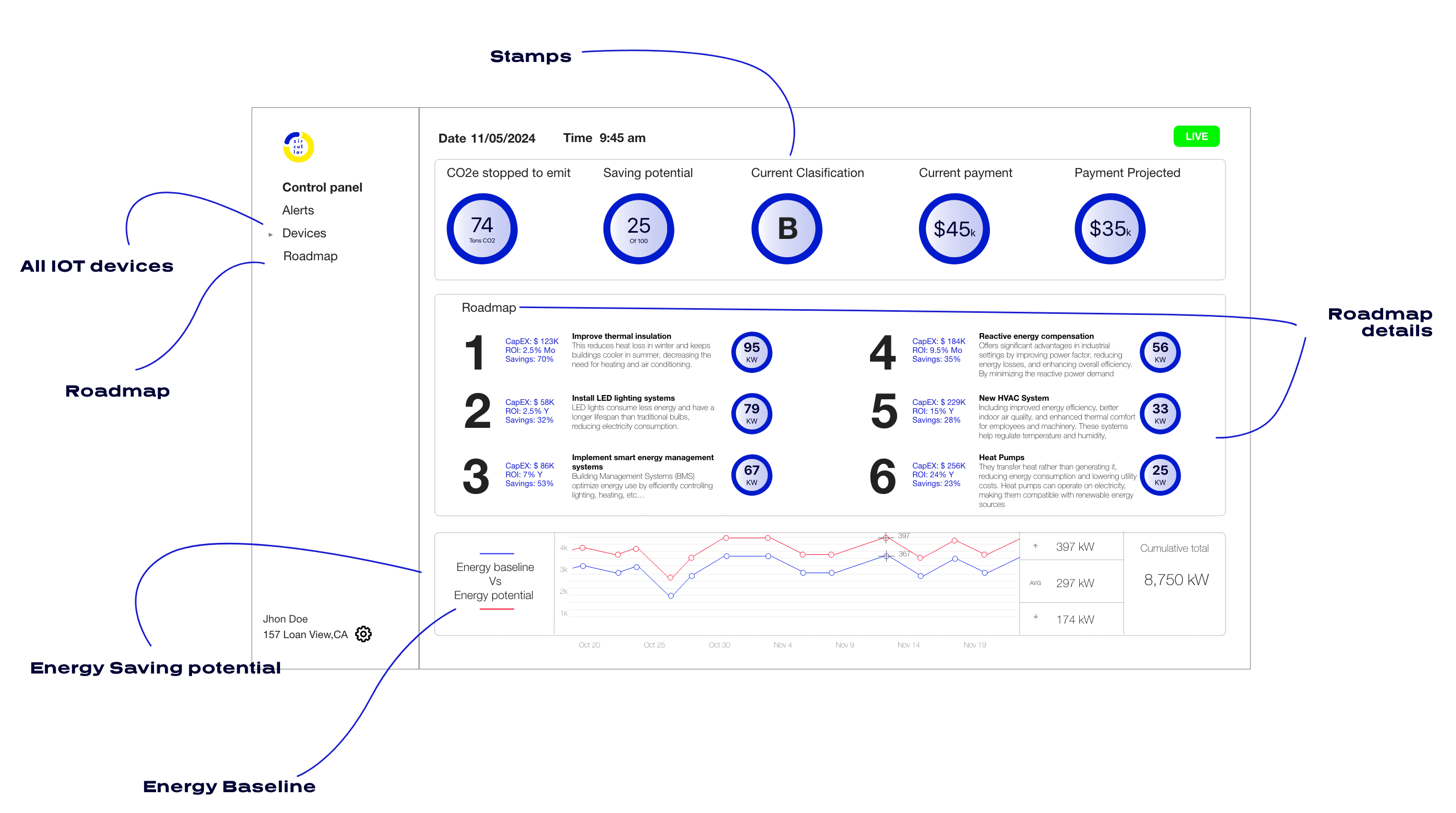

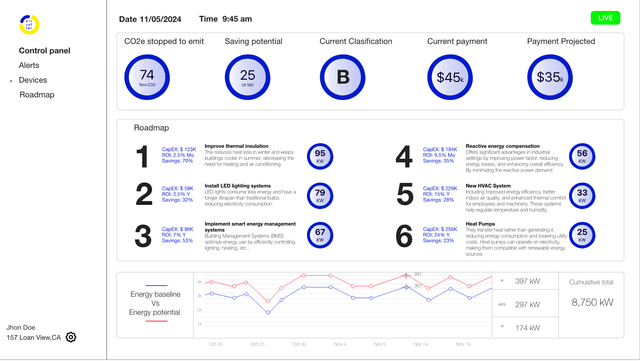

Dashboard

Features

Derived from actual energy consumption data.

Calculated based on measurable GHG improvement metrics.

Non-invasive technology for monitoring patent leaks.

Seamless integration with databases, sensors, and other measurement systems.

The code independently validates the data, eliminating the need for third-party verification.

Made for easy sharing

How it works

1. Sensor or Data Collection

Data can be obtained either through sensors or manual collection to establish an energy consumption baseline.

2. Platform

Provides real-time monitoring, customizable reports, AI-driven predictive maintenance, and step-by-step guidance to maximize ROI on energy projects.

3. Stamp

This stamp exclusively records improvements and, in combination with other tools (software and hardware), promotes further enhancements to reduce CO₂e and support the energy transition.

Interfaces with

1. Motors

2. Boilers (steam process)

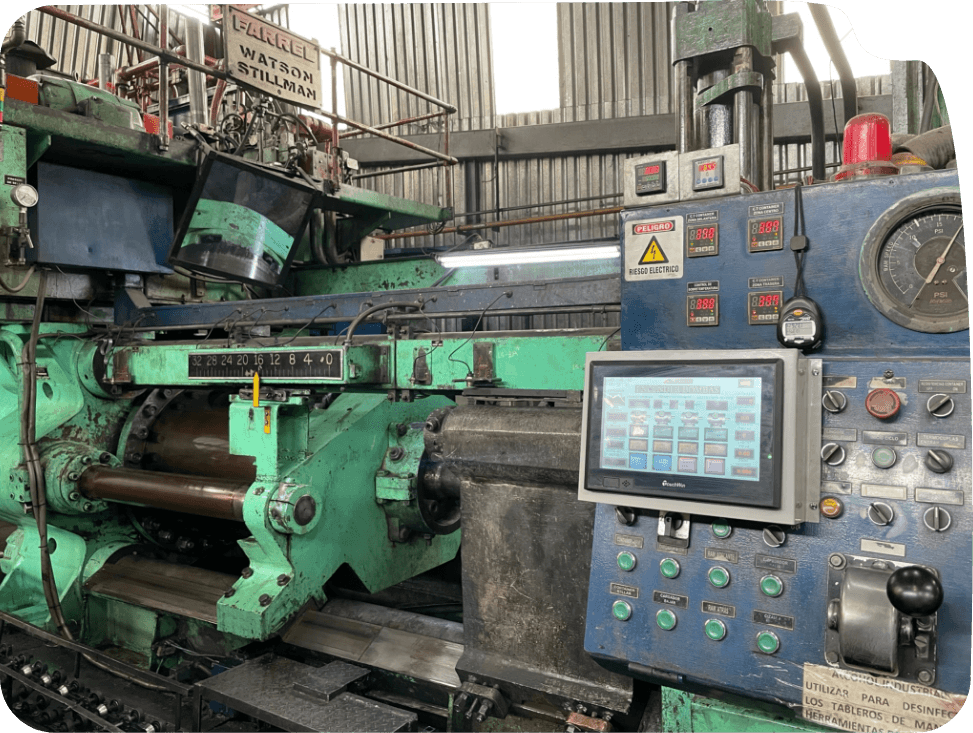

3. Hydraulic press

4. Pumps

5. Plastic injection machines

6. CNC machines

7. Packaging machines

8. Conveyors belt

9. Extrusion machines

10. Forging machines

11. Milling machines

12. Metal injection molding machines

13. Furnaces

14. Cold rooms

Validation Stamp

1. Easily shareable on your

social media posts

2. Displays percentage

improvements in energy

(kWh), CO2 reduction,

and cost savings

3. Real-time validation stamp

showing CO2 emissions

prevented

4.Enhances your

sustainability image

Case Study

Ecopetrol: The largest oil and gas company in Colombia

How could we optimize steam losses in an Industrial Plant (refinery), to reduce water consumption and greenhouse gas emissions associated with the process through a technology based on the Internet of Things (IoT)?

We set up the sensors and the platform with these features

- 1. Ultra low consumption

- 2. IPXX protection

- 3. Non-invasive connection

- 4. LoRaWan communication

- 5. Steam trap status

- 6. Steam trap condition

- 7. Amount of steam lost

- 8. Lost condensed steam

- 9. Calculation of CO2 emitted for each hour of failure

- 10. Calculate the water lost for each hour of failure.

- 11. Predictive maintenance

- 12. One sensor for many steam traps

- 13. Version without batteries

- 14. Patent pending

We achieved the following goals

Frequently Asked Questions

Links

We use cookies

We use cookies to ensure you get the best experience on our website. For more information on how we use cookies, please see our cookie policy.

By clicking "Accept", you agree to our use of cookies.